Efficiency & Sustainability: Air Compressors for Environmental & Operational Excellence.

At Kanyana Engineering. we understand the importance of efficiency and sustainability in our operations.

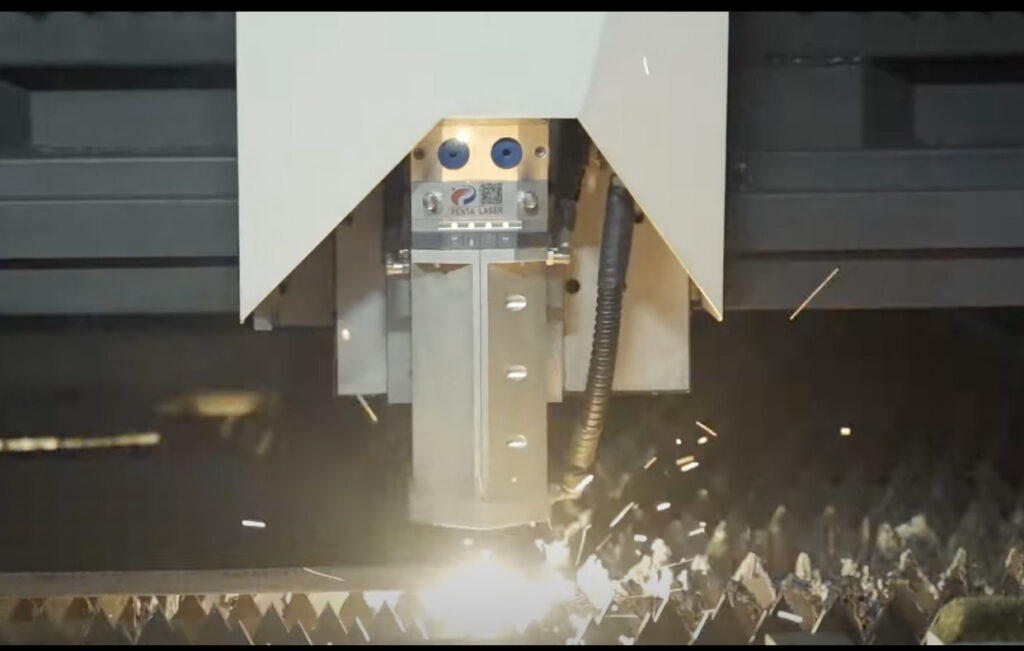

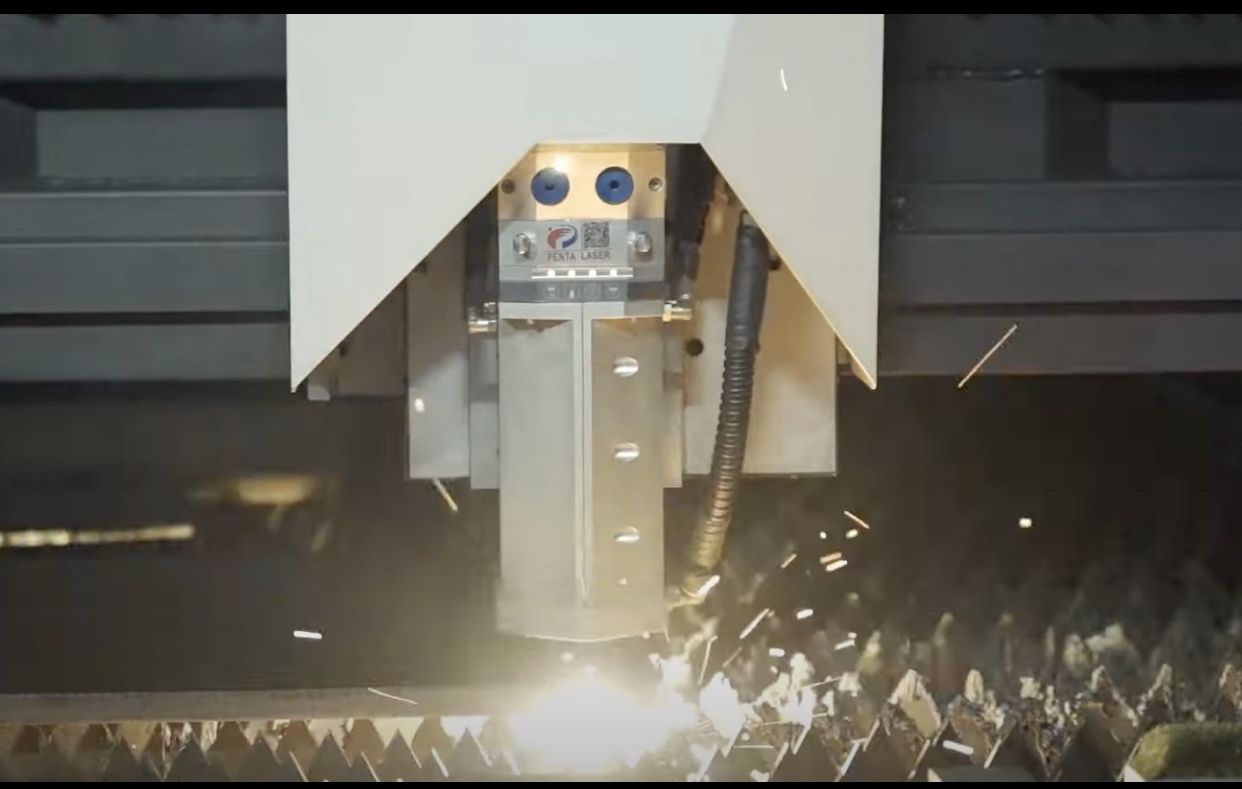

As a leading provider of metal laser cutting and fabrication services. we recognise the impact that our processes can have on the environment. That’s why we jumped at the chance to trial and invest in the state-of-the-art air compressor that not only enhances our productivity but also contribute to our commitment to sustainability.

Trialing the first in Australia the revolutionary air-mix gas compressor, we have already experienced significant benefits in terms of energy efficiency and waste reduction. These advanced compressors allow us to optimise our laser cutting ensuring that only the required amount of gas is utilised.

Although early days, through this system we are generating our own 100% pure oxygen and nitrogen this streamlined approach has not only reduced our energy consumption but also minimised wasteful heat generation, resulting in substantial cost savings for our business.

Monitoring the performance of the advanced compressor system over the next 12 months will determine if we swap out our other lasers with the more advanced compressor technology.

We are proud to contribute to a greener future while delivering high-quality metal cutting and fabrication solutions to our valued customers.

What obligations does a fabrication business have in relation to environmental sustainability?

At Kanyana Engineering, we believe that operational efficiency and environmental sustainability go hand in hand. As a reputable provider of metal laser cutting and fabrication services, we recognise our responsibility to minimise our impact on the environment. Our commitment to efficiency and sustainability, highlighting the benefits of our advanced air compression systems and discussing the obligations that fabrication businesses have in relation to environmental sustainability.

Investing in Energy-efficient Air Compressors: We have made significant investments in state-of-the-art air compressors, renowned for their energy efficiency and advanced technology. By minimising energy consumption and reducing wasteful heat generation, we have achieved substantial cost savings while reducing our carbon footprint.

Eliminating Oil Contamination: Our adoption of oil-free air compressors has revolutionised our manufacturing processes. With zero risk of oil contamination, we maintain the highest quality standards, ensuring reliable and precise fabrication outcomes. This not only enhances customer satisfaction but also minimises production setbacks, leading to improved efficiency and reduced waste.

Partnering for Long-term Performance: We understand that regular service and maintenance are essential for the longevity and performance of our air compressors. Through our partnerships, we have access to a team of expert technicians who provide proactive maintenance and timely repairs. By prioritising equipment longevity, we minimise downtime, repair costs, and the need for premature replacements.

Fabrication Businesses and Environmental Sustainability: As a fabrication business, we acknowledge our obligations in promoting environmental sustainability. Some key responsibilities include:

- Waste Reduction: We actively implement waste reduction strategies, such as recycling metal scraps and adopting sustainable packaging practices. By minimising waste generation, we contribute to a cleaner environment.

- Efficient Resource Management: We strive to optimise our resource utilisation, whether it’s electricity, water, or raw materials. By implementing energy-efficient technologies and monitoring resource consumption, we minimise our ecological footprint.

- Compliance with Environmental Regulations: We adhere to local and national environmental regulations, ensuring our operations align with sustainable practices. This includes responsibly managing hazardous substances and properly disposing of waste materials.

- Continuous Improvement: We are committed to ongoing improvement in our sustainability efforts. This involves regular monitoring, evaluation, and implementation of new technologies or practices to further minimise our environmental impact.

Conclusion: At Kanyana Engineering, we recognise that embracing efficiency and sustainability is not just a choice but an obligation. Through our investment in energy-efficient air compressors, elimination of oil contamination risks, and adherence to environmental responsibilities, we strive to be at the forefront of environmentally conscious fabrication practices. By prioritising the well-being of our planet, we aim to inspire other businesses in our industry to join us in building a sustainable future.