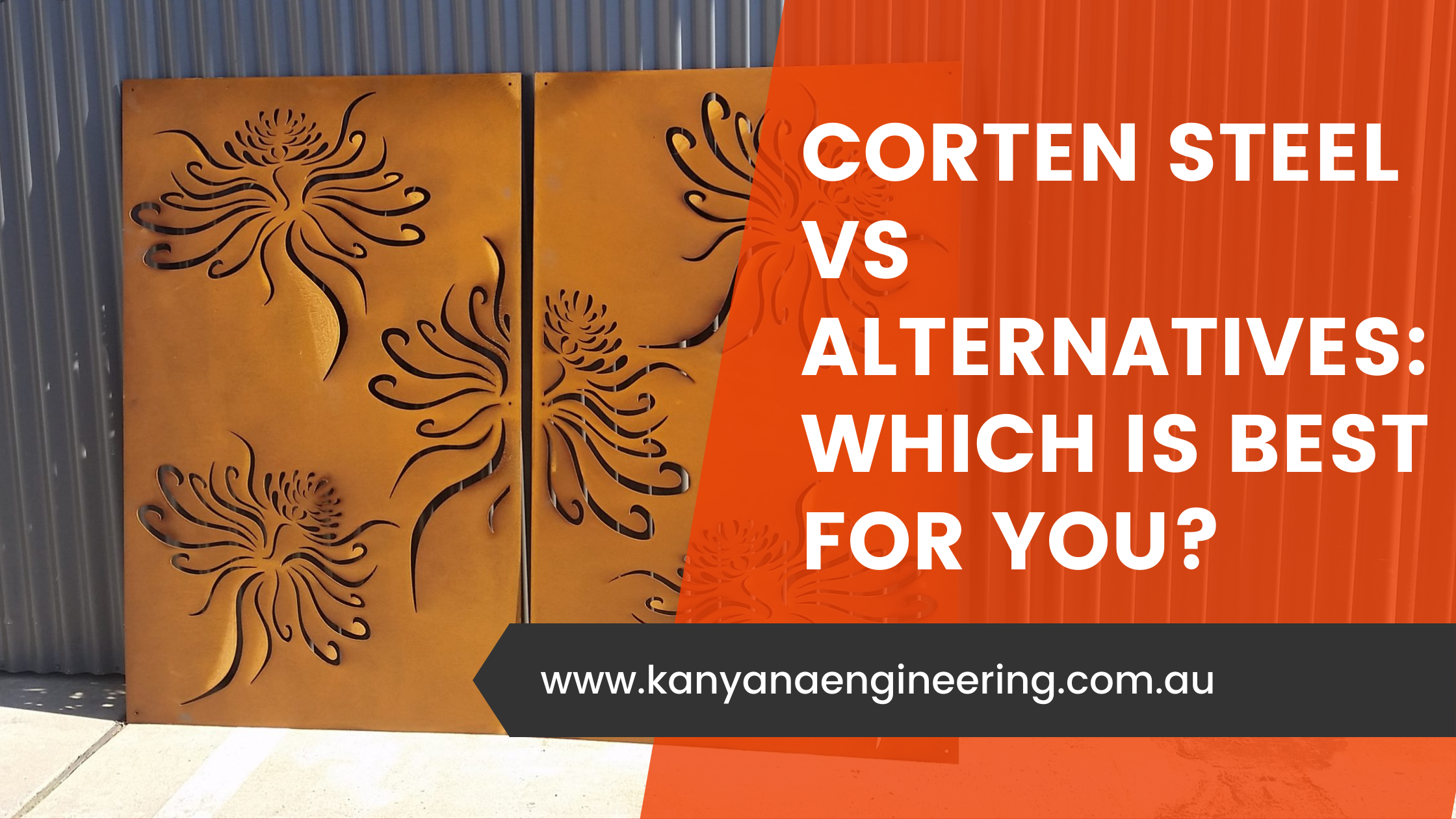

If you are looking for a durable material that gives off a rusted look without sacrificing structural integrity, then you might have heard of Corten steel. This steel is popular in the industry for its signature weathered look and low-maintenance nature.

For that reason, Corten steel metal art and outdoor sculptures are in high demand, and it’s also a popular material for planter boxes. When you understand what Corten steel is and what makes it special, it’s easy to see why it’s so popular in Australia.

But is Corten steel the only option when choosing a unique looking steel?

Although Corten steel is highly durable and produces a unique visual look, the fact that it is expensive, can cause staining to nearby surfaces and is not very environmentally friendly are all reasons people look to alternatives for Corten steel.

As such, we have created a brief guide to introduce you to different Corten Steel alternatives, how they compare to each other, their properties, and how you can make them look just like Corten steel, without having to worry about the environmental impacts of your choice.

Check our guide to learn more.

Why Choose An Alternative To Corten Steel?

You should consider choosing an alternative to Corten steel because it isn’t environmentally friendly, it’s more expensive than the alternatives, and it can stain nearby surfaces.

Corten steel is incredibly common in the construction industry as well as metal creative arts projects like outdoor sculptures. It’s visually very good looking and that comes from the natural patina that it develops, which helps it resist rust with little maintenance and upkeep. However, Corten steel isn’t perfect, and it’s well worth considering the alternatives for a few reasons.

Corten steel is significantly more expensive than other metals that can produce a similar finish. While it may not be as noticeable on small-scale projects, on larger construction sites and infrastructure projects, the difference in price can add up.

Over time, Corten steel will naturally develop an appearance that looks like rust. While this is a good look on steel, it doesn’t look great on walls and pathways. Unfortunately, Corten steel is known for having staining issues where the rust colour can leech and stain nearby surfaces, potentially ruining walls and floors.

Finally, although it’s recyclable and can be reclaimed, Corten steel is not overly environmentally friendly. Although the rust-like patina of the steel looks pleasing, the run-off is not great for the environment. Runoff that ends up in nearby drains, waterways, gardens and ponds can cause significant damage to the local ecosystem.

What Are The Best Corten Steel Alternatives?

A competitor brand of weathering steel, other types of steel being painted or coated and aluminium are the three main alternatives to Corten steel. These options produce similar looking finishes without being costly, bad for the environment or risking staining nearby surfaces.

- A Different Brand of Weathering Steel

- S355JOW – This is an equivalent weathering steel to Corten B (a specific grade of Corten steel). Similar to Corten, this builds a protective layer on the surface to protect the steel from oxidation and from rusting.

- S355JOWP – This grade of weathering steel is equivalent to Corten A. Due to the added phosphorus, it has very good self-protective properties that come with the layer of rust that forms on the surface. Commonly used in long-lasting infrastructure projects such as bridges.

- S355J2W – Another grade of weathering steel that is equivalent to Corten B. This steel is fully recyclable, and is used for both cosmetic purposes and load-bearing applications in structures.

- S355JOW – This is an equivalent weathering steel to Corten B (a specific grade of Corten steel). Similar to Corten, this builds a protective layer on the surface to protect the steel from oxidation and from rusting.

- Different Types of Steel that Can Instead Be Painted or Coated

There are many different types of steel on the market today, and many of these can be painted or coated to look like Corten steel. Some great options include:

- Stainless Steel – This is by far the most popular and well known among corrosion-resistant steels currently available in the market, due to its versatility. The principal chemical component in stainless steel alloys is Chromium. This chemical undergoes passivation on the surface of stainless steel plates that will form an inert patina that is not visible to the naked eye, but provides resistance to a multitude of corrosive conditions. This also protects it from both galvanic and acidic corrosion.

Stainless steel provides a proven reliability in protecting against a range of corrosives and comes in different grades available for specific applications. The thin protective layer provided by the Chromium in these alloys is self-repairing, which ensures that any corrosive effect will not spread into the rest of the material when a specific area on the surface is damaged. This surface does not flake over time.

The drawback is that stainless steel cannot be as hard-wearing as Corten steel (both A and B). Abrasion-resistant alloys are made available for custom applications but this also does not compare to Corten steel. Although subjective, most people find that the finish provided by stainless steel is also not as distinct or “appealing” as weathering steel. Despite all this, stainless steel remains a popular choice for its practically limitless application. - Carbon Steel – This is iron with anywhere from less than 1% carbon up to 2.5% carbon. When Chromium is added and reaches at least 10.5% of its composition, it then becomes stainless steel. If it has less than 10.5% Chromium, then it is, by definition, still Carbon Steel. Although Carbon steel is classified separate from Alloy steels (such as Stainless Steel), it is sometimes referred to as a ‘low-alloy’ steel due to some carbon steels containing other materials, albeit very low in composition.

Carbon Steel is very susceptible to rust due to the absence of corrosion resistant chemicals such as Chromium. However, this makes it far cheaper in addition to having its own set of varying mechanical properties based on its carbon content. - Stainless Steel – This is by far the most popular and well known among corrosion-resistant steels currently available in the market, due to its versatility. The principal chemical component in stainless steel alloys is Chromium. This chemical undergoes passivation on the surface of stainless steel plates that will form an inert patina that is not visible to the naked eye, but provides resistance to a multitude of corrosive conditions. This also protects it from both galvanic and acidic corrosion.

Stainless steel provides a proven reliability in protecting against a range of corrosives and comes in different grades available for specific applications. The thin protective layer provided by the Chromium in these alloys is self-repairing, which ensures that any corrosive effect will not spread into the rest of the material when a specific area on the surface is damaged. This surface does not flake over time.

The drawback is that stainless steel cannot be as hard-wearing as Corten steel (both A and B). Abrasion-resistant alloys are made available for custom applications but this also does not compare to Corten steel. Although subjective, most people find that the finish provided by stainless steel is also not as distinct or “appealing” as weathering steel. Despite all this, stainless steel remains a popular choice for its practically limitless application. - Carbon Steel – This is iron with anywhere from less than 1% carbon up to 2.5% carbon. When Chromium is added and reaches at least 10.5% of its composition, it then becomes stainless steel. If it has less than 10.5% Chromium, then it is, by definition, still Carbon Steel. Although Carbon steel is classified separate from Alloy steels (such as Stainless Steel), it is sometimes referred to as a ‘low-alloy’ steel due to some carbon steels containing other materials, albeit very low in composition.

Carbon Steel is very susceptible to rust due to the absence of corrosion resistant chemicals such as Chromium. However, this makes it far cheaper in addition to having its own set of varying mechanical properties based on its carbon content.

Carbon steel can be further classified into three types; Low-carbon steel (Less than 0.25% Carbon), Medium-carbon steel (0.25%-0.6% Carbon, and 0.6%-1.65% Manganese), and High-carbon steel (0.6%-1.25% Carbon, and 0.3-0.9% Manganese). Although Carbon Steel is wear-resistant, it is very susceptible to rust and corrosion. It also cannot reach the finish of either stainless steel, or Corten steel.

- Mild Steel – This is a ferrous metal made from Iron and Carbon, and is actually a form of Low-carbon steel. Although Mild Steel can develop the much admired warm and varied brown tones, Corten steel develops a slightly more orange tint due to its higher Copper content. As a low-carbon steel, it belongs to the family of weathering steels. By definition, weathering steels have additional alloying elements mixed together with the carbon and iron atoms, which give it better strength and more corrosion resistance than typical low carbon steel grades.

It should be noted that weathering steel should not be used in environments with high amounts of Chlorine, as the protective rust layer will not be able to withstand the corrosion, and will inevitably lead to premature failure of the structure. Weathering steel should also not be used in applications and use case scenarios which result in galvanic corrosion or those induced by extreme pH levels.

- Aluminium – Aluminium is another possible alternative that bears properties not present in steel. For instance, it is only ⅔ the weight of steel per square foot. Aluminium allows for custom shapes, routed letterings, and illumination — a degree of customisation not found in other metals. The material does not actually rust, and so the integrity of the material is never compromised. On the aesthetic side, a rusted look similar to Corten steel can be achieved through a controlled process that leaves out any degradation.

How Can I Make My Steel or Aluminium Look Like Corten Steel?

The most common ways of making steel and aluminium look like Corten steel are painting and powder coating the surface. We have detailed the processes below so you can determine which fits your needs better.

Powder Coating

Polyester Powder Coating (PPC) or powder coating, is one of the most common ways of painting steel, and involves applying a dry powder to a piece of steel, which is then transferred permanently onto the steel using an electrostatically charged tool.

Before the powder coating process begins, it’s important to prepare the steel. The powder coat will not be attracted to the steel correctly if the steel isn’t prepared properly. Any piece of steel that is going to be powder coated needs to be free of grease and dust.

The dry powder that is now electrostatically charged is drawn to the steel and forms a unique coating that is made permanent by heating the steel at close to 200°C.

Pros of Powder Coating as a Corten Alternative

- A Wider Visual Choice – PPC provides a wider selection of colours and finishes compared to the usual patina provided by Corten steel. Things such as planter edgings can be powder coated into any RAL colour, as well as specialist coatings which have specific textures and colours. Nothing else comes close to this level of flexibility.

- More Value for Money – Powder coating steel costs less than purchasing Corten steel. Although some specialised coatings cost more, and should be looked at in a project-specific manner.

Cons of Powder Coating as a Corten Alternative

- The Risk of Scratching – Although PPC offers more scratch resistance than ordinary paint, it still will not be durable enough to resist scratches from heavy and hard objects that scrape along the material. This is in contrast to Corten steel, whose colour is naturally occurring and does not scratch off.

- The Lack of Corrosion Resistance – This ‘con’ only applies when the steel was pre-coated with a Zinc Primer, as it scratches much more easily, which can expose the steel underneath and corrode. This is not so much of an issue for steel that is hot dip galvanised.

Painting

The Corten Paint Effect is a painting solution that gives mild steel, stainless steel, and even non-metallic materials and surfaces the rusty patina look that Corten Steel has.

The process involves priming the surface with several light layers of Corten until the rust colour you want starts to appear. During the priming stage, there is no need to wait between layers. With each layer, the surface’s colour will slowly transition from a red orange to a rusty shade. Darker areas will start to appear as more layers are applied. After you reach the desired shade of rust, you can apply the topcoat to seal the surface and give it some extra protection.

Pros of Painting as a Corten Alternative

- More Control Over the Look – Since you determine how many layers of Corten paint you apply onto the surface of the material, you get to control how dark or how light the shade is. You also have control over which areas to keep light, and which areas to darken.

- Cost-Effective – It goes without saying that painting a Corten effect on the surface of steel is cheaper than both powder coating and purchasing Corten Steel itself. This is the cheapest way to get the rusty look of Corten Steel.

Cons of Painting as a Corten Alternative

- Quicker Degradation and Weaker Adhesion – Unlike Corten Steel, the Corten paint effect will gradually deteriorate and lose its intended appearance due to natural wear and tear from the elements. It is also much weaker than PPC since the paint does not actually adhere due to an electrostatic charge, but by traditional spraying method. You’ll need to take extra care to seal and protect outdoor metal art which is painted.

- Prone to Error – Unlike PPC, which offers uniformity in appearance, conventional spray painting leaves a lot of room for human error. If you spray too much on a single area, you ruin the surface if you were aiming for a uniform shade. This is already on top of the fact that it is very hard to achieve a uniform surface due to the nature of the process.

Related Questions

Which Is Tougher Steel Or Aluminium?

Although aluminium offers better corrosion resistance, steel is without a doubt harder than aluminium, and is less likely to warp or bend from weight, heat, or other forces. Steel is still widely used because of its proven durability.

Can You Clear Coat Corten Steel?

Yes, you can clear coat or “seal” Corten Steel to prevent its rust stains from running down and staining parts of the structure. Clear coating Corten Steel also gives the surface a more finished look without doing away with its naturally occurring rusty patina.

Stunning Metal Art for Your Home or Garden

Looking for stunning laser cut steel or aluminium art for your indoor or outdoor spaces? Kanyana Engineering are the local experts in custom metal art, creating stunning and unique designs to suit every home. We also create custom commercial metal art for businesses and organisations. Choose from a range of wall art and fence topper designs, or request something completely unique from our talented team.

View our metal art designs here or contact Kanyana Engineering to find out more.

Disclaimer:

This article is published in good faith and for general informational purposes only. Kanyana Engineering does not make any warranties about the ongoing completeness and reliability of this information. Always seek specific advice on your metal fabrication project to ensure all variables are taken into consideration.

Graham Dawe is the Managing Director and Works Manager of Kanyana Engineering. With decades of experience in the metal fabrication industry, he is dedicated to keeping Kanyana at the forefront of the sector’s technological growth. Looking beyond the process itself to holistic, integrated CAD, CAM and MRP solutions, Graham believes Australian manufacturing has an enduring place on the global stage. In Kanyana Engineering’s state-of-the-art workshop in Mandurah, WA, Graham delivers an exceptional standard of work for commercial, industrial and government clients alike.